In this topic, we will display some Multiple-Choice Questions or Objective Questions on Shaper machine and its operations. I hope that you will get interest in reading the MCQ Questions.

Do you want to download the entire sheet, then find the PDF icon in the end of this article and then click on that PDF button.

Now, let’s start MCQ Questions.

MCQ Questions or Viva Questions on Shaper machine

Here, is the quiz on Shaper machine and its operation.

You will get help from this topic for semester examinations as well as for competitive examinations.

Overview of Shaper Machine

If you want more details on Shaper machine and its operation, please go ahead and read the following text.

What is a Shaper machine?

A shaper is one type of machine tool that has a single-point cutting tool and uses a linear relative motion between the cutting tool and the workpiece for machining operation.

Name some parts of the Shaper machine/ Shaping machine?

Ram, Ram locking handle, Ram adjustment nut

Tool, clapper box, tool slide, tool post

Base, Vice, table, column

Ram is the moving part of the shaper. On it, ram locking handle and ram adjustment nut are there.

What are the different types of Shaper machines?

Classification depending on the movement of Ram

Horizontal shaper

In horizontal shaper machine, ram moves horizontally.

Vertical shaper

In vertical shaper machine, ram moves vertically.

Classification depending on the movement of the table

Standard shaper

In standard shaper machine, the tables can be moved in two directions- horizontal and vertical.

Universal shaper

In universal shaper machine, the table can be moved horizontally, vertically and in any inclined axis. This shaper machine is suitable for different types of machining operation. Hence, the name of the shaper is universal shaper

Classification depending on the driving mechanism

Crank type shaper machine

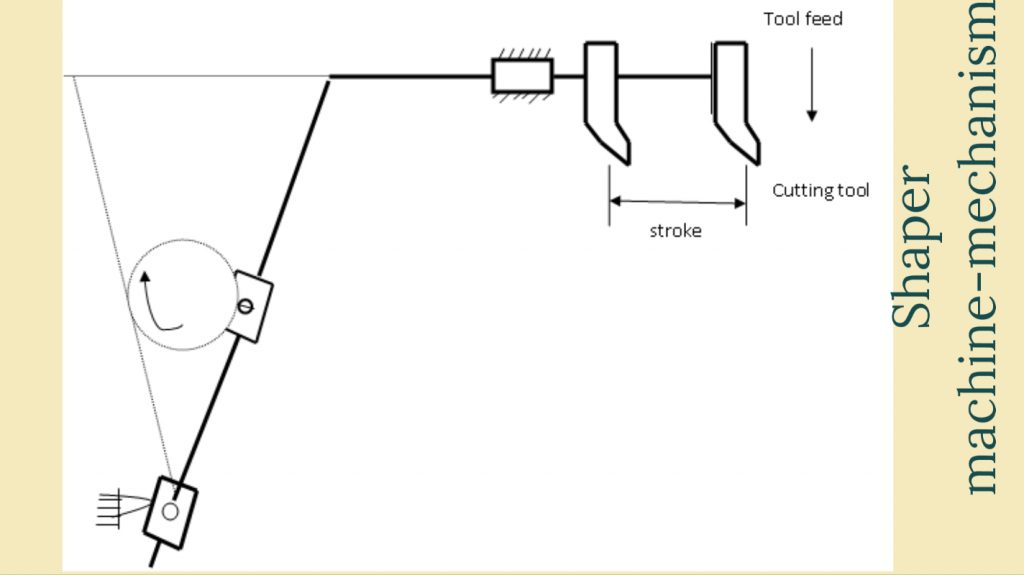

Here, stroke length = length over which cutting tool reciprocates. Crank type shaper machine uses crank mechanism for converting rotary motion into linear motion.

Geared type shaper

In gear type shaper, rack and pinion arrangement is there. Ram is reciprocating here. Speed and direction of the machine varies along with the numbers of gears.

Hydraulic type shaper

In this machine, hydraulic mechanism controls the reciprocating motion of the ram. The high pressure oil puts pressure on one side of the piston and thus it is being responsible for the reciprocating motion of the piston. This motion is transmitted to ram.

Classification based on the cutting stroke

Push cut shaper

This type of shaper machine removes the material from the job piece during the forward stroke. During the return stroke, the shaper does not cut the job piece.

This type of machine is commonly used.

Draw cut shaper

In this type of shaper machine, the cutting tool cuts during the backward stroke of the ram. Here, the tool is fixed in the tool head in the reverse direction.

What are the shaper machine operations?

The shaper machine operations are as following:

- Machining of:

- Horizontal surfaces

- Vertical surfaces

- Inclined surfaces

- Irregular surfaces

- Cutting key slots, keyways

- Making grooves

- Cutting gears

What is the quick return mechanism?

A quick return mechanism is a mechanism that produces reciprocating motion of the cutting tool. The cutting tool reciprocates in forward and backward direction.

When the cutting tool moves in a forwarding direction, it is a forward stroke. When the cutting tool moves in the backward direction, it is a return stroke or backward stroke. During forward stroke, the cutting tool removes the material from the workpiece. During return stroke or backward stroke, the cutting tool does not remove any material from the workpiece. Hence, the speed of the cutting tool during return stroke is higher than that of the cutting tool during forwarding stroke. Therefore, it is quick to return mechanism.

This mechanism converts rotary motion into a linear motion. It uses a system of links with three numbers turning pairs and one number sliding pair. This is a crankshaft mechanism.

What is a planer machine?

A planer is a machine tool that uses the linear relative motion between the cutting tool and the work piece. It is similar to shaper machine. But here, the machine is more rigid and the work piece moves.

What are the differences between a shaper machine and a planer machine?

Shaper machines the smaller jobs whereas planer machines heavier jobs.

For light cuts and finer feed, the shaper is appropriate whereas, for heavier cut and coarse feed, the planer is required.

Generally, the shaper runs on a quick return mechanism whereas the planer runs on a gear mechanism or hydraulic device.

At a time, shaper uses only one number single point cutting tool whereas, planer uses multiple single-point cutting tools at a time.

I hope that you will get interested in reading the objective questions and answers and can remember those easily. If you want me to write MCQ Questions on some other types, then please write in the comment box so that I can write on that too. Best wishes.