Are you looking for Multiple Choice Questions on Fitting Shop? Here in this article, we are going to place some MCQ Questions or Viva Questions on this topic so that you can get an excellent score in the examinations or in the viva.

Also, there is an online quiz test on Fitting Shop. Don’t miss it.

At the end of this article, you can download the MCQ sheet in PDF format. Now, let us jump into the MCQ section.

MCQ Questions or Viva Questions on Fitting Shop

- Center punch is a ______.

- holding tool

- cutting tool

- marking tool ✔️

- striking tool

- Try square is a ______.

- marking tool

- measuring tool

- both 1 and 2 ✔️

- cutting tool

- Ball peen hammer is a _______.

- striking tool ✔️

- cutting tool

- measuring tool

- marking tool

- Liquid chalk is used to _____.

- for marking and drawing the lines

- to whiten the surface to make the markings visible ✔️

- for cooling the surface

- none of the above

- Mallet is a ________.

- cutting tool

- marking tool

- measuring tool

- striking tool ✔️

- Which of the following instrument is used to measure the straightness of the surfaces of the job piece?

- center punch

- hammer

- try square ✔️

- odd leg caliper

- Which of the following instrument is used for making the markings permanent?

- scriber

- odd leg caliper

- outside caliper

- center punch ✔️

- Which of the following instrument is used to measure the length and width of the job piece?

- odd leg caliper and scale ✔️

- outside caliper and protector

- try square

- none of these

- Tap means –

- cutting from the edge

- internal threading ✔️

- making holes

- none of these

- How many taps are used while making an M.S gauge in the Fitting shop?

- 4

- 3 ✔️

- 2

- 1

- The tap which is used in the first operation while tapping is known as

- plug tap

- tapper tap

- primary tap

- both 2 and 3 ✔️

- Tap wrench is a _________________.

- cutting tool

- marking tool

- holding vice ✔️

- measuring vice

- The tap which is used in the last operation while tapping is known as

- plug tap ✔️

- tapper tap

- primary tap

- both 2 and 3

- Which of the following is used to measure angles?

- odd leg caliper

- outside caliper

- bevel protector ✔️

- all of the above

- Which tool is used as a marking tool?

- scriber ✔️

- mallet

- outside caliper

- odd leg caliper

Quiz on Fitting Shop

Here is the quiz for you.

You may consider this as a test of 20 marks. Thus, you can take preparation for the viva questions on “Fitting shop” and can perform the job in a better way.

For getting clarification on the MCQ questions, you may read the following text.

Fitting Shop

The different parts of an object are manufactured in the fitting shop. The parts are shaped and brought to the required dimensions. Finally, these parts are assembled to get the final product.

Students will perform the operations on the bench vice. Therefore, these operations are called fitting work.

Bench vice in the Fitting shop

Students will fix the job material on a work table and will perform all the operations. Hence, this device is also a job-holding device. We call it bench vice.

It consists of a cast steel body, two jaws, handles, screws, and a nut.

One jaw is movable and the other one is fixed. Jaws are also cast steel. The handle, a square threaded screw, and a nut are made of mild steel.

A jaw plate with teeth, a separate plate made of cast steel, is fixed to the jaws by means of set screws. When they are worn out, they are replaced.

The screw passes through the nut that is fixed with the movable jaw creating the movement of the vice.

Job in the Fitting shop: making a gauge on an M.S plate

Here, students will learn how to make a gauge on a mild steel plate in the fitting shop along with the different types of fittings operations.

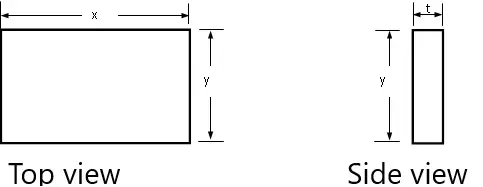

Raw material diagram

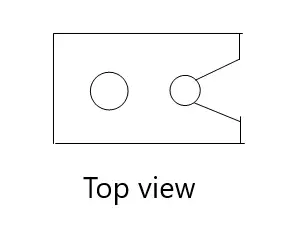

Finished job diagram

Name of the Tools used in the Fitting shop

Measuring and marking instruments

- Surface Plate

- Steel Rule

- Try Square

- Odd leg caliper

- Scriber

- Bevel protector

- Center punch

- Ball peen hammer

Cutting instruments

- Half-round file

- Hack saw

- Twist drill

- Taps

Other measuring instruments (not used in this job)

- Vernier calipers

- Micrometer

Different types of gauges used for measuring dimensions are:

- Feeler gauge

- Radius gauge

- Screw pitch gauge

- Drill gauge

Procedure

Measuring the raw material

First students have to measure the raw material and will note the dimensions on their lab copy.

Checking the straightness of the surfaces

They will check the straightness of all the surfaces of the job piece with the help of a try square. It is an ‘L’ shaped instrument.

Students will set the job piece in the try square.

The right angle of the try square will have to be in line with any of the two surfaces of the job piece.

Filing and checking the straightness of the surfaces

Filing is one type of cutting operation.

Students will perform the filing operation on all the surfaces until they are not coming in a straight position.

After filing, If no light passes through the gap between the surfaces of the try square and the job piece, then the surfaces are in a straight position. Students have to file all the surfaces till they achieve this condition.

Measurement of the job piece after the completion of filing.

Students have to measure the job piece once again for recording the final dimensions.

Marking

Temporary marking

Take the job piece; put the white liquid chalk on any one surface. Give some time to make it dry.

Then, draw the lines on the white surface as per the requirement with the help of the steel rule and scriber.

Draw one centerline lengthwise and along the width, and draw two lines( 15 mm from the edges) as per instructions with the help of the odd leg caliper and steel rule.

An intersection between one horizontal line and two vertical lines will give you the two center points of the holes.

From the center point of the second hole, draw 600 angles with the help of a bevel protector and steel rule.

Permanent marking

Place the center punch on the two numbers centers of the holes and press it with the help of a ball-peen hammer. A permanent mark will be visible then.

Place the center punch on the inclined lines of the 600 angle and press it with a ball-peen hammer to get the permanent mark.

Repeat the above procedure on those two inclined lines to get the permanent marking for those willing lines.

Thus, the students will get permanent markings.

Drilling

To make the holes, use twist drills.

The material of the twist drills is high-speed steel.

It may be of straight or taper shank type.

Take the job to the drilling machine.

The point of the twist drill and the center point of the hole should be in line.

Switch on the drill machine.

Thus, the students can create two holes.

Sawing and making the ‘V’ cut

- Students will have to place the job piece in an inclined way in the bench vice.

- With the help of a hack saw, students will cut the inclined portion as per the marking.

- Thus students will get the sides of the ‘V’ portion.

Finishing the inclined surfaces of the ‘V’ cut

Students will do the filing of the sides of the ‘V’ portion with the help of a half-round file for making smooth surfaces.

Tapping

- Take the taps and tap the wrench

- For cutting internal threads in a drilled hole, students will use taps.

- Taps are of three types. They are- the tapper tap or first tap, intermediate tap, bottoming tap, or plug tap.

- A thread is specified by its size, shape, and pitch.

- M20X2.5 of thread means that the nominal diameter is 20 mm and the pitch is 2.5 mm metric head.

- Select the correct size tap with the desired pitch.

- Fit the job piece in the bench vice in such a way that from the top view both holes are clearly visible.

- Insert the first tap within the first hole with the help of a tap wrench.

- Start turning clockwise by applying downward pressure.

- Students will use a tap wrench for holding the taps.

- The tap wrench where the taps are held has also two jaws-one is fixed and the other one is a movable jaw.

- By displacing the movable jaw, students can fix the taps in the tap wrench.

- Check the alignment of the tap and the hole axis. You may apply lubricant while tapping.

- The tap is to be turned half around clockwise and then it should be brought back so that chips break.

- Students will repeat this process with an intermediate and plug tap to complete the threading.

- Be careful while removing the taps.

- The material of the taps are high carbon steel or high-speed steel

- .Thus the students can make the taps.

Safety rules for the Fitting shop

- Always wear leather shoes, not sandals.

- Don’t wear loose clothes.

- Know the correct posture before filing the job piece.

- Hold the hack saw straightway. Don’t make it inclined.

Conclusion

The Multiple-Choice Questions on Fitting Shop mentioned here are the basic questions of the Fitting Shop. I hope that it will help you in clearing the viva during the semester examination. All the students from different streams have to perform this experiment in Fitting Shop in the first year. I hope that the article- Multiple-choice questions on Fitting Shop will remove your boredom in the workshop. Best wishes!

Thanks ma’am… Really helpful for our exam

Thank you Sagar. Best wishes!